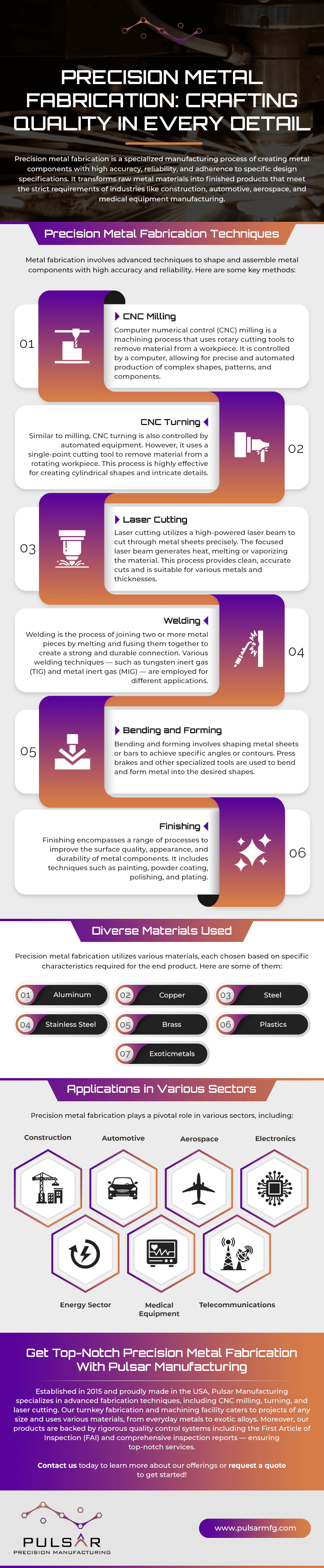

Precision metal fabrication is a specialized manufacturing process of creating metal components with high accuracy, reliability, and adherence to specific design specifications. It transforms raw metal materials into finished products that meet the strict requirements of industries like construction, automotive, aerospace, and medical equipment manufacturing.

In this blog, we delve into the intricacies of precision metal fabrication, including techniques employed, materials used, and applications in diverse sectors.

Precision Metal Fabrication Techniques

Metal fabrication involves advanced techniques to shape and assemble metal components with high accuracy and reliability. Here are some key methods:

1. CNC Milling

Computer numerical control (CNC) milling is a machining process that uses rotary cutting tools to remove material from a workpiece. It is controlled by a computer, allowing for precise and automated production of complex shapes, patterns, and components.

2. CNC Turning

Similar to milling, CNC turning is also controlled by automated equipment. However, it uses a single-point cutting tool to remove material from a rotating workpiece. This process is highly effective for creating cylindrical shapes and intricate details.

3. Laser Cutting

Laser cutting utilizes a high-powered laser beam to cut through metal sheets precisely. The focused laser beam generates heat, melting or vaporizing the material. This process provides clean, accurate cuts and is suitable for various metals and thicknesses.

4. Welding

Welding is the process of joining two or more metal pieces by melting and fusing them together to create a strong and durable connection. Various welding techniques — such as tungsten inert gas (TIG) and metal inert gas (MIG) — are employed for different applications.

5. Bending and Forming

Bending and forming involves shaping metal sheets or bars to achieve specific angles or contours. Press brakes and other specialized tools are used to bend and form metal into the desired shapes.

6. Finishing

Finishing encompasses a range of processes to improve the surface quality, appearance, and durability of metal components. It includes techniques such as painting, powder coating, polishing, and plating.

Diverse Materials Used

Precision metal fabrication utilizes various materials, each chosen based on specific characteristics required for the end product. Here are some of them:

- Aluminum: This lightweight and corrosion-resistant metal is known for its versatility and excellent thermal conductivity.

- Copper: This ductile and malleable metal is renowned for its exceptional electrical conductivity.

- Steel: This material is essential for fabricating structural components and heavy-duty parts due to its high strength and durability.

- Stainless steel:This corrosion-resistant alloy is recognized for its durability and hygienic properties.

- Brass: Characterized by its attractive appearance, good corrosion resistance, and malleability, brass typically finds applications in decorative elements.

- Plastics: These materials are lightweight and versatile with electrical insulating properties.

- Exoticmetals: High-performance alloys like titanium, Hastelloy, Inconel, and Monel may also be used for metal fabrication. These exotic metals are used in industries where standard materials may not suffice due to extreme conditions, demanding specifications, or a combination of both.

Applications in Various Sectors

Precision metal fabrication plays a pivotal role in various sectors, including:

- Construction: structural elements and components such as beams, columns, and connectors

- Automotive: chassis, engine parts, and intricate details in vehicle interiors

- Aerospace: airframe components, engine parts, and intricate structures

- Medical equipment: diagnostic and surgical equipment, medical instrument parts, braces, and frames

- Electronics: device casings, connectors, and heat sinks

- Energy sector: turbine components, energy storage systems, and transmission infrastructure

- Telecommunications: antennas, satellite systems, and communication devices

Get Top-Notch Precision Metal Fabrication With Pulsar Manufacturing

Established in 2015 and proudly made in the USA, Pulsar Manufacturing specializes in advanced fabrication techniques, including CNC milling, turning, and laser cutting. Our turnkey fabrication and machining facility caters to projects of any size and uses various materials, from everyday metals to exotic alloys. Moreover, our products are backed by rigorous quality control systems including the First Article of Inspection (FAI) and comprehensive inspection reports — ensuring top-notch services.

Contact us today to learn more about our offerings or request a quote to get started!