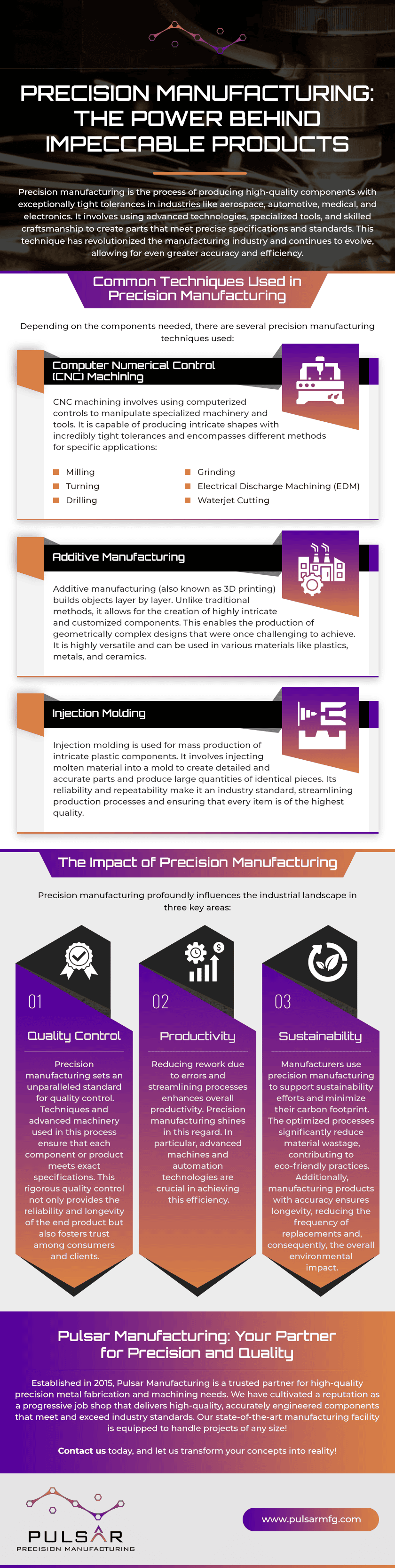

Precision manufacturing is the process of producing high-quality components with exceptionally tight tolerances in industries like aerospace, automotive, medical, and electronics. It involves using advanced technologies, specialized tools, and skilled craftsmanship to create parts that meet precise specifications and standards. This technique has revolutionized the manufacturing industry and continues to evolve, allowing for even greater accuracy and efficiency.

In this article, we take a closer look at precision manufacturing, its common techniques, and its significant impact on industries.

Common Techniques Used in Precision Manufacturing

Depending on the components needed, there are several precision manufacturing techniques used:

Computer Numerical Control (CNC) Machining

CNC machining involves using computerized controls to manipulate specialized machinery and tools. It is capable of producing intricate shapes with incredibly tight tolerances and encompasses different methods for specific applications:

- Milling: CNC milling is a fundamental technique in precision manufacturing. It involves rotating cutting tools to remove material from a workpiece like metals, plastics, and composites.

- Turning: CNC turning rotates the workpiece while a stationary cutting tool shapes it. This method crafts cylindrical components like shafts and bolts.

- Drilling: CNC drilling creates accurate holes in workpieces, which is vital for assembly and functionality.

- Grinding: CNC grinding utilizes abrasive wheels to achieve ultra-precise finishes. It ensures superb surface quality, suitable for applications where aesthetics matter.

- Electrical Discharge Machining (EDM):This process uses electrical discharges to shape materials. Its non-contact method creates fine details without affecting the material’s properties.

- Waterjet Cutting: This CNC technique uses high-pressure water mixed with abrasives to cut through materials like metals, ceramics, and plastics.

Additive Manufacturing

Additive manufacturing (also known as 3D printing) builds objects layer by layer. Unlike traditional methods, it allows for the creation of highly intricate and customized components. This enables the production of geometrically complex designs that were once challenging to achieve. It is highly versatile and can be used in various materials like plastics, metals, and ceramics.

Injection Molding

Injection molding is used for mass production of intricate plastic components. It involves injecting molten material into a mold to create detailed and accurate parts and produce large quantities of identical pieces. Its reliability and repeatability make it an industry standard, streamlining production processes and ensuring that every item is of the highest quality.

The Impact of Precision Manufacturing

Precision manufacturing profoundly influences the industrial landscape in three key areas:

1. Quality Control

Precision manufacturing sets an unparalleled standard for quality control. Techniques and advanced machinery used in this process ensure that each component or product meets exact specifications. This rigorous quality control not only provides the reliability and longevity of the end product but also fosters trust among consumers and clients.

2. Productivity

Reducing rework due to errors and streamlining processes enhances overall productivity. Precision manufacturing shines in this regard. In particular, advanced machines and automation technologies are crucial in achieving this efficiency.

3. Sustainability

Manufacturers use precision manufacturing to support sustainability efforts and minimize their carbon footprint. The optimized processes significantly reduce material wastage, contributing to eco-friendly practices. Additionally, manufacturing products with accuracy ensures longevity, reducing the frequency of replacements and, consequently, the overall environmental impact.

Pulsar Manufacturing: Your Partner for Precision and Quality

Established in 2015, Pulsar Manufacturing is a trusted partner for high-quality precision metal fabrication and machining needs. We have cultivated a reputation as a progressive job shop that delivers high-quality, accurately engineered components that meet and exceed industry standards. Our state-of-the-art manufacturing facility is equipped to handle projects of any size!

Contact us today, and let us transform your concepts into reality!