Safety is one of the most important considerations when designing and manufacturing aircraft parts and components. Every aircraft must meet the most exacting technical specifications, and there is no room for human error in the manufacturing and assembly processes. That’s because any flaws, gaps, or uncertainties can have disastrous consequences.

CNC machining is a suitable manufacturing technique for the aerospace industry due to the high degree of precision required. Moreover, this method’s ability to achieve highly tight tolerance levels for plastic and metal components enables it to provide industry-leading solutions.

This article will discuss the advantages and applications of the aerospace CNC machining process.

What Is Aerospace CNC Machining?

Aerospace CNC machining involves the precise production of components with the durability and strength required for mission-critical applications. It also encompasses the idea that aircraft parts such as bearings, hinges, clamps, and other custom parts must be made of high-quality materials. Moreover, this process is necessary to ensure that all components operate properly and do not pose a risk.

Engine parts and other components subjected to high stresses during flight must be made of lightweight, high-temperature-resistance materials. As a result, aluminum was once the most preferred material in the aerospace industry because it is light and inexpensive. Although it is still used today, composite materials and alloys rapidly overtake it as the ideal manufacturing substance. Titanium, Kovar, stainless steel, copper, and bronze are now the most commonly used for aerospace machining.

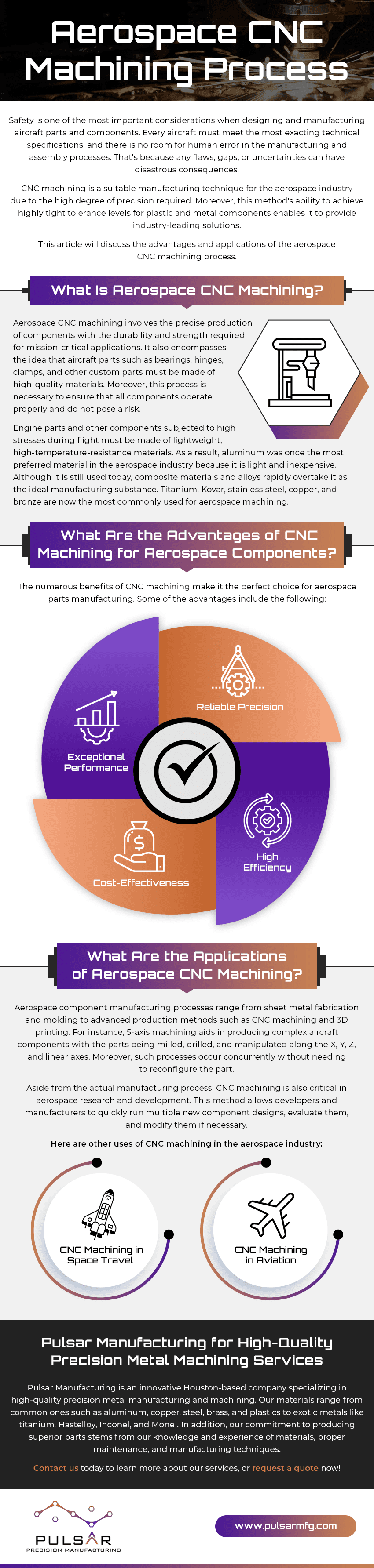

What Are the Advantages of CNC Machining for Aerospace Components?

The numerous benefits of CNC machining make it the perfect choice for aerospace parts manufacturing. Some of the advantages include the following:

Reliable Precision

Continuous advancements in CNC technology enable manufacturers to produce high-precision aerospace components. Furthermore, improved accuracy and quality assurance reduce production defects and result in long-lasting parts with tight dimensional tolerances.

Exceptional Performance

Aerospace components must meet rigorous, detailed technical requirements to avoid part collapses or malfunctions. With CNC machining, manufacturers can produce high-performance parts from difficult-to-machine materials like titanium and high-temperature superalloys.

High Efficiency

A single CNC machine can perform multiple machining operations. Besides that, CNC machining achieves greater speed through automation, which shortens production time and improves efficiency.

Cost-Effectiveness

The combination of precision and rapid manufacturing helps with per-part costs by reducing waste production, reworks, and labor costs. Increased output also increases profitability.

What Are the Applications of Aerospace CNC Machining?

Aerospace component manufacturing processes range from sheet metal fabrication and molding to advanced production methods such as CNC machining and 3D printing. For instance, 5-axis machining aids in producing complex aircraft components with the parts being milled, drilled, and manipulated along the X, Y, Z, and linear axes. Moreover, such processes occur concurrently without needing to reconfigure the part.

Aside from the actual manufacturing process, CNC machining is also critical in aerospace research and development. This method allows developers and manufacturers to quickly run multiple new component designs, evaluate them, and modify them if necessary.

Here are other uses of CNC machining in the aerospace industry:

CNC Machining in Space Travel

CNC machining is essential in producing the most technologically sophisticated shuttles and rockets for various space missions. The parts required for these vehicles must function correctly and ensure the spacecraft’s safety to protect the crew and the vehicle itself.

CNC Machining in Aviation

Accuracy is an essential element of aircraft structures — whether for cargo planes, fighter jets, or passenger airlines. These precision requirements apply to all aspects of aircraft production, from the innermost layer to the outer body. CNC machining aids in the production of seemingly insignificant parts that are critical to the engine’s operation. For example, an airplane’s engine must keep the plane in the air for the duration of the flight. As a result, the machine must adequately process and use fuel.

Pulsar Manufacturing for High-Quality Precision Metal Machining Services

Pulsar Manufacturing is an innovative Houston-based company specializing in high-quality precision metal manufacturing and machining. Our materials range from common ones such as aluminum, copper, steel, brass, and plastics to exotic metals like titanium, Hastelloy, Inconel, and Monel. In addition, our commitment to producing superior parts stems from our knowledge and experience of materials, proper maintenance, and manufacturing techniques.

Contact us today to learn more about our services, or request a quote now!